Manufacturing Innovation: Personal Assistance in 3D Printing

Introduction:

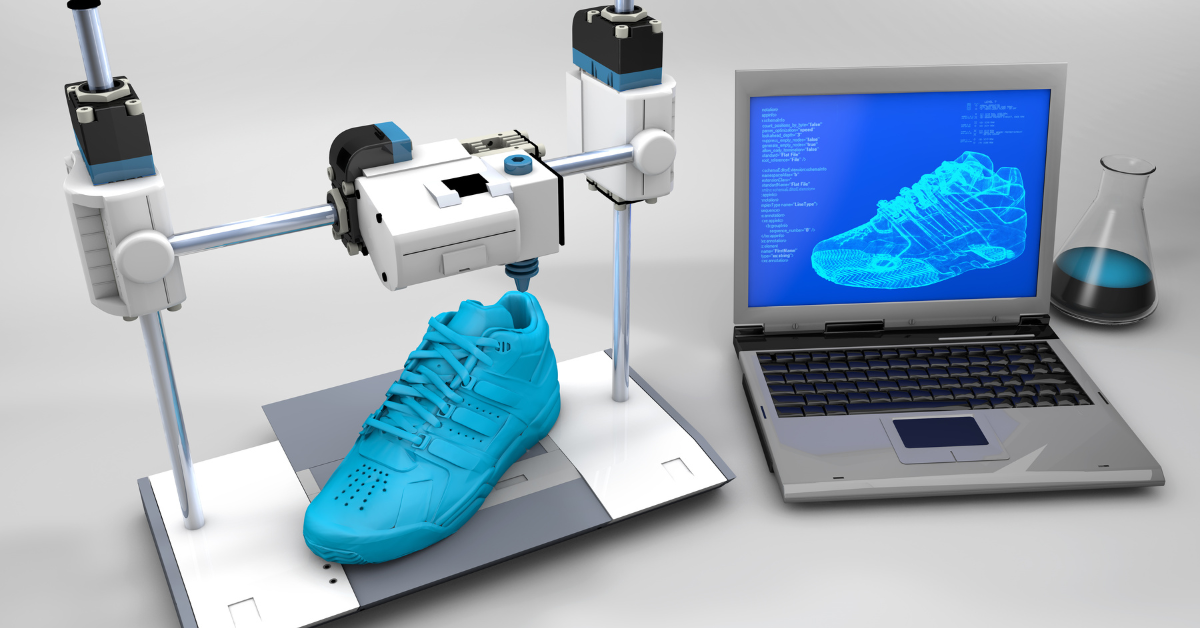

The manufacturing sector is undergoing a significant transformation due to technological advancements, increased demand for customization, and rapid prototyping. 3D printing, powered by AI, is transforming the industry by promoting efficiency and creativity.

Personal assistance technologies, powered by AI, are enhancing the capabilities of 3D printing in several key areas. These digital assistants can streamline the design process, optimize printing operations, and provide real-time monitoring and adjustments. By harnessing the power of AI, manufacturers can now leverage 3D printing in ways that were previously unimaginable, from creating complex, bespoke items with ease to significantly reducing production times and costs.

The design phase is critical in 3D printing, where the complexity of creating models that are both functional and optimized for printing can be a significant challenge. AI-powered personal assistants are transforming this process by offering intuitive design suggestions, automating the optimization of designs for 3D printing, and even predicting potential issues before printing begins. This level of support not only accelerates the design process but also enhances creativity, allowing designers to explore more innovative solutions without the constraints of traditional manufacturing methods.

3D printing operations can greatly benefit from personal assistance technologies. These assistants can manage and schedule print jobs, monitor material usage, and ensure that printers are operating efficiently. Furthermore, by analyzing data from previous print jobs, AI-driven assistants can recommend adjustments to printing parameters to improve quality, reduce material waste, and shorten print times. This optimization contributes to more sustainable manufacturing practices and lower production costs.

Quality control is paramount in manufacturing, and 3D printing is no exception. Personal assistants equipped with AI can continuously monitor the printing process, detecting anomalies and making real-time adjustments to correct any issues. This capability significantly reduces the risk of defects and ensures that the final product meets the required standards. Moreover, by analyzing data over time, these assistants can identify patterns and suggest improvements to the printing process, further enhancing product quality.

3D printing offers customization and rapid prototyping, enhancing personal assistance technologies and enabling manufacturers to quickly respond to market demands and shorten product development cycles.

As both 3D printing technology and AI continue to evolve, the potential for personal assistance in manufacturing will only grow. Future developments could see even more advanced predictive analytics, enabling manufacturers to anticipate market trends and adjust their production strategies accordingly. Additionally, the integration of virtual and augmented reality with personal assistance technologies could revolutionize the design process, allowing for even more immersive and intuitive creation of 3D-printed objects.

The integration of personal assistance technologies into 3D printing is revolutionizing manufacturing by streamlining design, optimizing operations, enhancing quality control, and facilitating customization, paving the way for future growth and innovation.

#ManufacturingInnovation #3DPrintingTech #AIPoweredManufacturing #PersonalAssistanceTech #DesignOptimization #QualityControl #CustomizationRevolution #RapidPrototyping #SustainableManufacturing #FutureOfProduction #TechDrivenCreativity #SmartManufacturing #DigitalTransformationInManufacturing #EfficiencyIn3DPrinting #InnovativeManufacturingSolutions

Registered Office Address